Описание

MAIN APPLICATIONS

- Food and non food retail, shopping malls (airports restaurants, shops, …)

- Industrial buildings

- Hospitals

DESCRIPTION

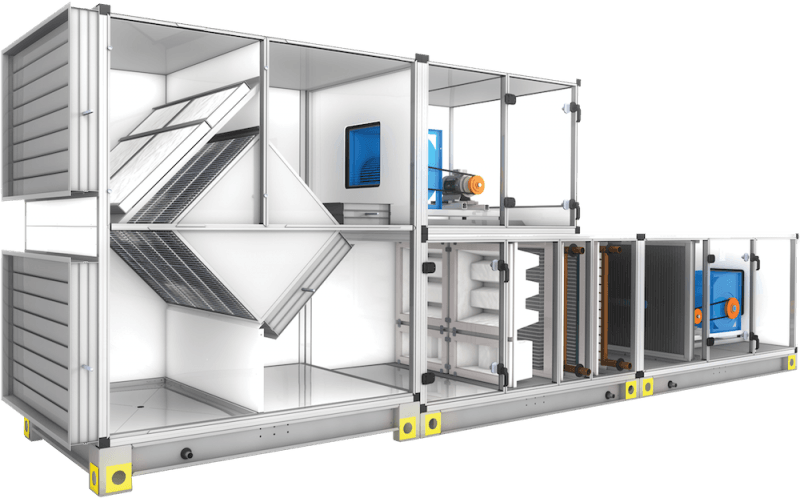

- Modular air handling units

- Adapted to any air treatment application : ventilation, filtration, heating, cooling, humidity and recovery, and allowing the best choice in relation to the requested face velocity

- Wide range : 44 sizes from 1 000 up to 100 000 m3/h with total pressures up to 2 500 Pa (28 basic sizes and 16 low profile sizes)

- CLEANAIR LX units developed and dimensioned in length, width and height, using a module of 160 mm

- If necessary, distinctly rectangular cross-section fitted with ow profile units, in order to reduce the height while increasing the width

MAIN COMPONENTS

Base frame:

- Galvanized steel “C” shaped frame 2,5 mm thickness according to the unit length.

- Unit supplied with four corner feet with lifting holes suitable for 2” diameter thickness walled steel pipe

Frame and panels:

- Frame and panel structure developed with particular care on thermal insulation and resistance

- Casing in aluminium with 60 mm sandwich panels, insulated with injected polyurethane to 45 kg/m3 density or mineral wool to 90 kg/m3 density

- Internal surface of the unit is completely smooth and no screws are visible inside the unit

- Gasket between the panels to ensure airtight seal, to eliminate thermal bridges, to reduce air leakages and to eliminate dust accumulation

- 3 way corner joint in glass fibre reinforced nylon

- EN 1886 Classification for standard construction:

– Mechanical resistance: D1

– Leakage : L1/L2

– Filter by-pass: F9

– Transmittance: T2

– Thermal bridges: TB2 or TB3 or TB4 depending on the casing (see selection data sheet) - Auxiliary drain pan in ABS and connected with the main drain pan to collect condensate of heat exchanger and control valve(s).

- Externally positioned control board : easily accessible